The universal-use recycling line for processing all types of films, fibres, fleece, monofilaments, multifilaments, tapes, and fabrics as well as for massive lump waste and large moulded parts. This versatile line can process all thermoplastics, for example PE, PP, PS, PA, and others. It is used especially for hard-to-grind materials and products.

The material is fed without pre-cutting to the single-shaft cutter by conveyor belt, film reel feeder or edge trim cyclone. A hydraulically driven pusher presses the material against the rotor, where it is cut between the rotary and stationary knives. The rotary shaft is cooled to facilitate the cutting of materials with low melting points. However, cooling is kept to the necessary minimum so that the energy generated in cutting can be utilised in the extrusion process.

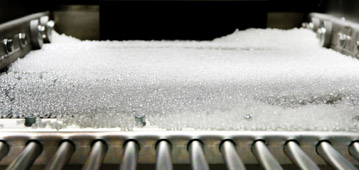

The cut material is then fed continuously to the extruder. The machine is designed so that overloading and underloading are avoided.

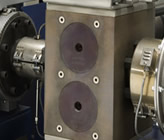

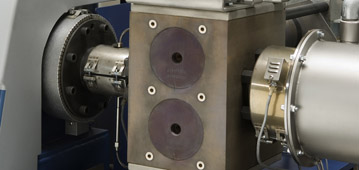

The recoSTAR universal series comprises four machine sizes which together cover an output range of 150 – 1300 kg/h. Each machine can be equipped with degassing, high vacuum, backflushing filter and any one of three pelletising systems.